个人简介:

王烨,工学博士,副教授,博士生导师,美国TMS会员,中国知网专家库成员,四川省学术和技术带头人后备人选,四川省科技专家库成员。

Email:wangye@scu.edu.cn

伟德bevictor中文版望江校区伟德bevictor中文版322室(610065)

伟德bevictor中文版江安校区基础教学楼B109室(610225)

教育简历:

2003.09-2007.07,昆明理工大学材料科学与工程专业,获得工学学士学位。

2007.09-2010.05,昆明理工大学材料物理化学专业,获得工学硕士学位。

2010.09-2015.09,日本东京大学材料工学专业,获得博士学位。

2018.05-2020.04,伟德bevictor中文版化学工程与工艺专业,博士后出站。

工作简历:

2015.10-2018.08,bevictor伟德官网冶金工程系,特聘副研究员。

2018.09-今,bevictor伟德官网化学工程系,副教授,硕士生导师。

2022.08~2023.08,江苏省常州市新北区科技局副局长,挂职。

主要研究领域:

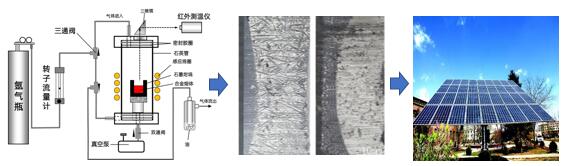

1.太阳能级多晶硅电池制备与稀有金属的分离提纯:

利用冶金法选择性高效去除多晶硅中杂质,低成本制备太阳能级多晶硅。应用:多晶硅太阳能电池

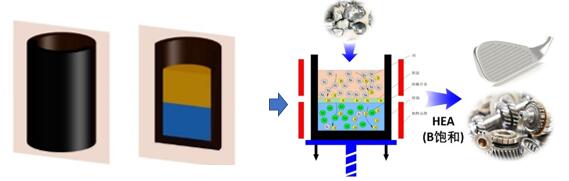

2.高熵合金制备及应用

通过成分和工艺调控,制备兼具高强度和高韧性的超性能高熵合金材料。应用:航空航天、机械关键零部件、涂层等。

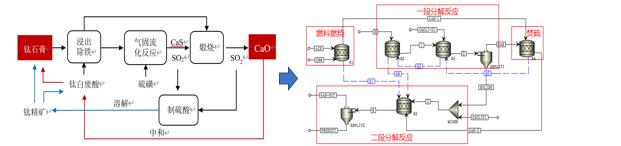

3.工业副产物的高值循环利用

针对钛石膏、磷石膏、钛白废酸、赤泥等工业固废带来的环境问题,利用新型冶金、化工处理技术,结合工业布局特点,实现废弃物的高值制备和元素的循环利用。

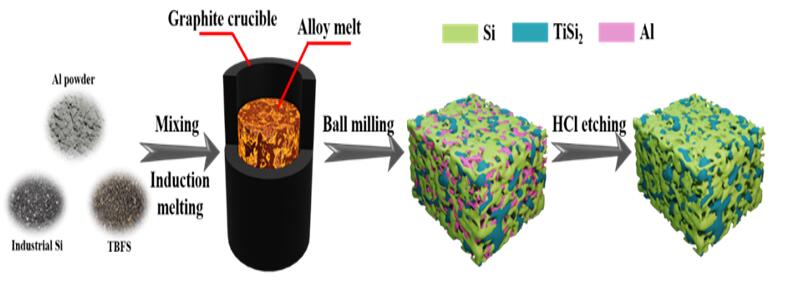

4.微米级大容量低成本硅基电池负极研发

随着电动汽车和储能系统的快速发展,传统电池负极材料,如石墨,已经无法满足日益增长的能量需求。硅作为一种具有高理论比容量的储能材料备受关注。项目提出利用廉价的含钛高炉渣、切割硅废料等作为原材料,通过高温可控反应、高能球磨、喷雾干燥、定向刻蚀等技术制备出微米级硅基合金负极材料。特殊结构可以缓解硅在充放电过程中的体积膨胀问题,将为快充动力汽车、储能系统等领域提供高性能的电池材料,在环境保护和资源回收方面也具备潜在的经济和社会效益。

5.工业设计与经济评价

主要工作业绩:

课题组以坚持绿色环保发展和建设新能源新材料美丽世界为教学和科研理念,主要从事于利用冶金法制备新能源材料、太阳能级多晶硅造渣精炼、稀有金属的分离提纯及废弃物循环利用回收等领域的研究,迄今在Carbon, ACS Applied Materials and Interfaces, Inorganic Chemistry, Journal of Cleaner Production, Industrial Engineering Chemical Research, Hydrometallurgy,Solar Energy and Solar Cells, Metallurgical and Material Transaction B等国际国内高水平学术期刊及学术会议上发表论文40余篇,授权中国发明专利8项,项目经费400余万。

承担项目情况:

项目类别 |

批准号 |

项目名称 |

起止年月 |

金额(万) |

项目状态 |

排名 情况 |

国家级 |

22378272 |

利用高熵合金定向凝固去除硅废料中硼杂质的协同机制研究 |

2024.1-2027.12 |

50 |

在研 |

主持 |

国家级 |

516041761003405 |

挥发性渣气去除冶金级多晶硅中杂质的物理化学研究 |

2017-2019 |

20 |

结题 |

主持 |

省级 |

24GJHZ0432 |

微米级大容量低成本多孔硅钛锂电池负极研发 |

2024.1-2025.12 |

20 |

在研 |

主持 |

省级 |

2021YFH0131 |

高温萃取法制备高纯硅与高强度HEA机理与工艺研究 |

2021.4-2023.3 |

20 |

结题 |

主持 |

省级 |

2018SZ0285 |

硫磺还原分解钛白石膏制硫酸技术及硫铁钙资源循环利用 |

2017-2019 |

20 |

结题 |

主持 |

省级 |

2019YFH0149 |

利用光伏硅废弃物和高炉钛渣合成TiSi2-Si锂离子电池负极材料 |

2019-2021 |

30 |

结题 |

主研 |

市级 |

2022-YF05-00265-SN |

用于降解VOCs的高熵合金纳米催化剂研制 |

2023.6-2024.5 |

10 |

在研 |

主持 |

市级 |

2016-HM01-00399-SF |

微波活化高炉渣矿化CO2 |

2017-2019 |

10 |

结题 |

主持 |

市级 |

2018CDPZH-24 |

硫铁矿(或硫磺)分解钛白石膏及硫铁钙资源内循环利用技术 |

2018-2020 |

10 |

结题 |

主持 |

校级 |

0030704153019 |

梯度烧结-纳米微晶新型人工骨的构筑及应用研究 |

2020-2021 |

10 |

结题 |

主持 |

校级 |

20822041A4028 |

利用挥发性渣精炼去除冶金级多晶硅中杂质的物理化学研究 |

2015-2018 |

30 |

结题 |

主持 |

校级 |

伟德bevictor中文版通识教育核心课程项目 |

《科学技术简史:从石器到量子》 |

2020-2021 |

20 |

结题 |

主持 |

校级 |

研究生教学改革项目 |

面向新工科的泛在学习与多维度《技术经济学》课程教学改革探索 |

2018-2020 |

0.6 |

结题 |

主持 |

企业 |

H240308 |

高盐废水资源化处理研究 |

2023.6-2025.12 |

300 |

在研 |

主持 |

企业 |

21H0012 |

钛石膏在建材中的应用技术研究 |

2021.1-2023.1 |

100 |

结题 |

主持 |

政府 |

H230921 |

常州国家高新区合作咨询 |

2023.9-2025.8 |

20 |

在研 |

主持 |

政府 |

H211037 |

什邡市“十四五”能源与产业发展规划编制 |

2021.10-2022.12 |

50 |

结题 |

主持 |

企业 |

H230642 |

生物质润滑油产学研合作 |

2023.6-2024.5 |

5 |

结题 |

主持 |

企业 |

H230320 |

自清洁抗震材料研发 |

2023.3-2024.3 |

5 |

结题 |

主持 |

国家级 |

2017YFB0307504 |

低电耗电化学制氟及五氟化磷生产技术示范 |

2017-2020 |

205 |

结题 |

第四 |

国家级 |

2016YFB0600904 |

CO2矿化非碱性矿的离子迁移规律及过程强化基础 |

2016-2021 |

904 |

结题 |

第十 |

研究成果:

论文(一作或通讯论文):

(1) Fan Gao, Dingyue Zhang, Hao Zhang, Caiqin Gao, Gang Huang, Ziqiang Zhang, Yong Liu, Ye Wang*, Mauricio Terrones, Yanqing Wang*. Liquid bath-assisted combustion activation preparation of nitrogen/sulfur-doped porous carbon for sodium-ion battery applications, Carbon, 2024, 229, 119481. https://doi.org/10.1016/j.carbon.2024.119481.

(2) Mouqiao Zheng, Qijie Yi, Ye Wang*, Wenxiang Tang*, Xiaodong Ma, Youngjae Kim. Engineering oxygen vacancies of Co-Mn-Ni-Fe-Al high-entropy spinel oxides by adjusting Co content for enhanced catalytic combustion of propane, Inorganic chemistry, 2024. https://pubs.acs.org/doi/10.1021/acs.inorgchem.4c02659.

(3) Jiangmei Yi, Shuai Li, Wenyu Yang, Yujunyao Wang, Hao Hu, Hua Meng, Ye Wang*. Study on strengthening the crystallization process of removing F and P from phosphogypsum produced by dihydrate–hemihydrate wet process. Metallurgical and Materials Transactions B, 2024. https://doi.org/10.1007/s11663-024-03151-w.

(4) Yong Liu, Yanjun Zhong, Zhihua Zeng, Pan Zhang, Hao Zhang, Ziqiang Zhang, Fan Gao, Xiaodong Ma, Mauricio Terrones, Ye Wang*, and Yanqing Wang*. Scalable Synthesis of a Porous Micro Si/Si-Ti Alloy Anode for Lithium-Ion Battery from Recovery of Titanium-Blast Furnace Slag. ACS Applied Materials & Interfaces, 2023 15 (47), 54539-54549,DOI: 10.1021/acsami.3c13643

(5) Yong Liu, Zhihua Zeng, Yanjun Zhong, Wenxiang Tang, Ye Wang*, Zhiyuan Chen, Wenhui Ma, Kazuki Morita. Mechanism study on a recyclable and clean process for boron removal from industrial-grade silicon using CrMnFeNiMe high-entropy alloy, Journal of Cleaner Production, 420 (2023): 138330. Web. https://doi.org/10.1016/j.jclepro.2023.138330.

(6) 向梦琪,孟华,王烨,孟宪章,白宇航,王余军垚,张译丹. 钛石膏中铁浸出动力学及其酸浸循环工艺研究[J]. 无机盐工业. 2023, doi:10.19964/j.issn.1006-4990.2023-0141.

(7) Qipeng Li, Cong Feng, Quanle Cao, Wei Wang, Zihan Ma, Yonghao Wu, Tinghan He, Yangtian Jing, Wenxuan Tan, Tongxiao Liao, Jie Xing, Xiangfeng Li, Ye Wang*, Yumei Xiao, Xiangdong Zhu, Xingdong Zhang, Strategies of strengthening mechanical properties in the osteoinductive calcium phosphate bioceramics, Regenerative Biomaterials, Volume 10, 2023, rbad013, https://doi.org/10.1093/rb/rbad013.

(8) 王烨,陈桂鑫,徐玥瑶,王冠智,张柏林. 多学科交叉通识教育对老员工创新能力影响的实证研究—以《科学技术简史:从石器到量子》通识课为例[J].中文科技期刊数据库(全文版)教育科学, 2023(3):6.

(9) Ye Wang, Genkuan Ren, Bing Jiang, Lin Yang, Zhiye Zhang, Xinlong Wang, Yanjun Zhong, Zhiyuan Chen, Xiushan Yang, Kazuki Morita, Wenhui Ma. Fabrication of a nanosize hematite pigment via waste ferrous sulfate recycling using sulfur reduction. Metallurgical and Material Transaction B 54, 22–28 (2023). https://doi.org/10.1007/s11663-022-02584-5.

(10) Mengqi Xiang, Zike Han, Ye Wang*, Wenxiang Tang, Zhiyuan Chen, Wenhui Ma, and Kazuki Morita, Novel CrFeCoNiSi6/Si system for boron removal from metallurgical silicon feedstock, Industrial & Engineering Chemistry Research, 2022, 61 (9), 3412-3417, DOI: 10.1021/acs.iecr.1c04930

(11) Zhihua Zeng, Ye Wang*, Junjie Shi, Shimiao Zhou, Wenxiang Tang, Zhiyuan Chen, Wenhui Ma, Danyang Li, Kazuki Morita, Enhanced boron removal by CrMnFeNi-based high-entropy alloys during purification of silicon, Separation and Purification Technology, 279, 2021, 119682, https://doi.org/10.1016/j.seppur.2021.119682.

(12) Zhihua Zeng, Mengqi Xiang, Dan Zhang, Junjie Shi, Wei Wang, Xiaopeng Tang, Wenxiang Tang, Ye Wang*, Xiaodong Ma, Zhiyuan Chen, Wenhui Ma, Kazuki Morita, Mechanical properties of Cantor alloys driven by additional elements: a review, Journal of Materials Research and Technology, 15, 2021, 1920-1934, https://doi.org/10.1016/j.jmrt.2021.09.019.

(13) Hui Chen, Xizhi Yuan, Kazuki Morita, Yanjun Zhong, Xiaodong Ma, Zhiyuan Chen, Ye Wang*. Reaction mechanism and kinetics of boron removal from molten silicon via CaO-SiO2-CaCl2 slag treatment and ammonia injection. Metallurgical and Material Transaction B 50, 2088–2094 (2019). https://doi.org/10.1007/s11663-019-01639-4

(14) Ye Wang, Fang Chen, Xiaodong Ma, Guoquan Zhang*, Recovery of nitric and acetic acids from etching waste solutions using a synergistic system consisting of N235 and TRPO in cyclohexane, Hydrometallurgy, 185, 2019, 23-29. https://doi.org/10.1016/j.hydromet.2019.01.015.

(15) Zike Han,Jianqiu Gao,Xizhi Yuan,Yanjun Zhong,Xiaodong Ma,Zhiyuan Chen,Dongmei Luo,Ye Wang*. Microwave roasting of blast furnace slag for carbon dioxide mineralization and energy analysis[J]. RSC Advances, 10, 17836–17844. 10.1039/D0RA02846K.

(16) Ye Tao, Bin Jiang, Xiushan Yang, Xiaodong Ma, Zhiyuan Chen, Xinlong Wang, Ye Wang*, Physicochemical study of the sustainable preparation of nano-Fe2O3 from ferrous sulfate with coke. Journal of Cleaner Production, 255, 2020, 120175. https://doi.org/10.1016/j.jclepro.2020.120175.

(17) Hui Chen, Kazuki Morita, Xiaodong Ma, Zhiyuan Chen, Ye Wang*. Boron removal for solar-grade silicon production by metallurgical route: A review. Solar Energy Materials and Solar Cells, 2019(203), 110-169. https://doi.org/10.1016/j.solmat.2019.110169.

(18) 张雨露,王烨*,杨林,杨秀山,王辛龙. 硫磺分解氟石膏制高纯氧化钙联产硫酸的研究, 无机盐工业, 2020(7): 70-73.

(19) 王烨,吉旭,顾武安,黄青松,泛在学习在《技术经济学》新工科课程的教学实践[J]. 教育现代化, 2020, 007(006):57-61. https://doi.org/10.1654/j.cnki.2095-8420.2020.06.021

(20) Ye Wang, Tianming Wan, Yanjun Zhong, Xiaodong Ma, Zhiyuan Chen, Xinlong Wang*. Environmental sustainability of renewable phosphogypsum by CaS - Characterization and process optimization. Journal of Thermal Analysis and Calorimetry. 139, 3457–3471 (2020), https://doi.org/10.1007/s10973-019-08718-3.

(21) Zhong Yanjun, Zheng Linxin, Wu Zhenguo, Guo Xiaodong, Wang Xinlong, Wang Ye*, & Zhong Benhe. (2019). Microwave-assisted rheological phase synthesis of LiFe0.5Mn0.3Co0.2PO4 /C cathode materials for lithium ion batteries. Materials Research Express, 6(3), 035003, https://doi.org/10.1088/2053-1591/aaf30c.

(22) 王烨, 王俊哲, 张志业, et al. 不同气氛对硫铁矿与磷石膏反应过程软化温度的影响研究[J]. 无机盐工业, 2017(12):57-60.

(23) Chen H, Wang Y*, Morita K. Model implementation of boron removal using CaCl2-CaO-SiO2 slag system for solar-grade silicon [J], Metallurgical and Material Transaction B, 48, 3219–3227 (2017). https://doi.org/10.1007/s11663-017-1105-7.

(24) 李如虎, 李春, 岳海荣, 梁斌, 吕莉,王烨*. 温度制度对钾长石-硫酸钙-碳体系焙烧提钾、还原脱硫以及CO2矿化的影响,化工矿物与加工,2017(4), 20-24.

(25) Ye Wang, Junzhe Wang, Zhiye Zhang, Lin Yang, Xiushan Yang, Benhe Zhong, Xingjian Kong, Xinlong Wang*. Investigation of the fusion characteristics of ash in the reduction of pyrite and phosphogypsum [J]. Journal of Sustainable Metallurgy, 3, 737–752 (2017). https://doi.org/10.1007/s40831-017-0138-0.

(26) Ye Wang, Kazuki Morita, Measurement of the phase diagram of the SiO2-CaCl2 system and liquid area study of the SiO2-CaO-CaCl2 system, Metallurgical and Materials Transactions B, 2016, 47(3):1542-1546.

(27) Ye Wang, Kazuki Morita, Measurement of CaO-SiO2-CaCl2 slag density by an improved Archimedean method,Journal of Mining and Metallurgy. Section B: Metallurgy. 51 (2) B (2015) 113-116

(28) Ye Wang, Kazuki Morita, Reaction Mechanism and Kinetics of Boron Removal from Molten Silicon by CaO-SiO2-CaCl2 Slag Treatment [J]. Journal of Sustainable Metallurgy, 2015, 1(2):126-133.

(29) Ye Wang, Xiaodong Ma, Kazuki Morita. Evaporation Removal of Boron from Metallurgical-Grade Silicon Using CaO-CaCl2-SiO2 Slag [J]. Metallurgical and Materials Transactions B, 2014, 45(2):334-337.

(30) Ye Wang, Wenhui Ma, Jijun Wu, Yang Zhou, Bin Yang, Yongnian Dai, Morita Kazuki. Research on boron removal of metallurgical grade silicon with silica by ozidizing refining[C]// China-russia Symposium on Advanced Materials & Technologies. 2009.

(31) 王烨, 伍继君, 马文会, et al. 太阳能级硅制备技术与除硼工艺研究现状[C]// 全国冶金物理化学学术会议. 2008.

(32) 王烨, 李秋霞, 杨斌, et al. 真空下低价氯化铝生成及其分解热力学简化研究[J]. 真空, 2009, 46(4):61-65.

授权发明专利

(1)王烨,杨贵翔,韩子柯,任永生,王辛龙,利用高熵合金提纯多晶硅的方法,ZL 2019102582211.1

(2)王烨,韩子柯,陈辉,袁熙志,杨林,钟艳君,许德华,王辛龙,微波活化高炉渣的方法,ZL2018110878754。

(3)王烨,李朝荣,杨林,凌浩瀚;钟艳君;王辛龙,制氟阳极及其制备方法,ZL2018111355335。

(4)王烨,张雨露,杨林,凌浩瀚,钟艳君,王辛龙,改善制氟阳极性能的方法,ZL201811135532.0

(5)王烨,陈辉,袁熙志,王辛龙,一种挥发性渣气协同提纯多晶硅的方法,ZL201810272495.1。

(6)伍继君,马文会,王烨等,一种硅中硼杂质的去除方法,ZL200910094519.X。

(7)王烨,曾治华,张雨露,杨林,杨秀山,陶冶,王辛龙,一种利用钛石膏制备氧化钙并联产硫酸的方法,ZL201911200030.6。

(8)王烨,刘勇,向梦琪,李琪鹏等,一种低碳型超硫酸盐水泥及其制备方法,以及水泥砂浆,ZL202110834212.X。

实验设备

实验室优秀员工

研究生团队

实验室生活

招生专业:

化学工程与工艺,化学冶金和材料技术等相关专业